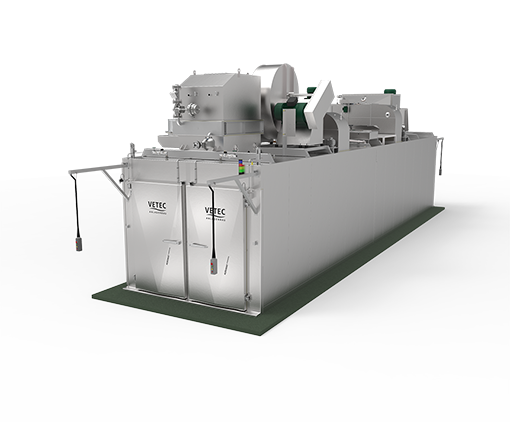

AEROMAT COMPOUND - Hot smoking and cooking system in combination with intensive cooling system

The AEROMAT COMPOUND from VETEC ANLAGENBAU combines the well-known and proven technology of the hot smoking and cooking system with that of an intensive cooling system. In the first step, your product goes through the following processes: Reddening, drying, warm and hot smoking, scalding, cooking and hot air cooking in the hot smoking and cooking area. The food is then cooled down with shower water and air in the intensive cooling area. The semi-continuous transport system makes the AEROMAT COMPOUND for a flexible solution for your meat production.

Our technology & your benefits

The AEROMAT COMPOUND is at the heart of the efficient design of your production processes. The automatic transport of your products from hot to cold treatment makes a decisive contribution to consistent product quality and minimal weight loss. At the same time, intervention in the process is reduced, as transportation to the cooling system enables hygienic separation between the raw and production areas without external intervention. There is no need for staff to enter hot chambers, which significantly improves working conditions.

You only place your trolleys on the first place of the hot smoking and cooking section. The electric transport system moves each trolley to the correct position. After loading the system, start your program.

As soon as the heat treatment is complete, the AEROMAT COMPOUND The automatic doors to the intensive cooling system open and transport your products to the intensive cooling section. There, they are immediately cooled and dried to packaging temperature with shower water and cold air. At the end of the program, the transport system transfers the trolleys to you individually for the subsequent process, e.g. packaging. Due to the flexible transport in both directions, only the hot smoking or intensive cooling section can be used if production changes require it.

The transport system works absolutely reliably even with very high trolley weights.

ECO heat recovery CON

By preheating the fresh air, energy consumption can be reduced by up to 30 %.

Smoke generator

We offer smoulder smoke generators, liquid smoke systems, steam smoke generators and friction smoke generators for a wide range of smoking processes.

Cold water circulation

An energy-saving recycling system for packaged products in water-impermeable casings, in which cold shower water is treated and fed back into the process.

Ethernet Connection

Messages are sent by email to a defined email distribution list.

Heating mode

The AEROMAT COMPOUND is available in steam-heated, direct gas-heated and electrically heated versions.

Cold smoking device

A cold smoking unit is used for products that are gently smoked at low temperatures.

Cooking equipment

Cooking with steam enables a cooking system that is used not only to cook the products, but also to disinfect the plant house.

Fully automatic CIP system

The fully automatic central cleaning system with rotary nozzles in the chamber achieves optimum hygiene. A foam pump is available as an option.

MICROMAT ANALYZER - Central control and documentation system

Complex production processes and widely distributed system components are reduced to a safe and convenient overall view for the operator.

Door variants

For different requirements, we offer a fully automatic lifting and lowering door, the roller shutter door or a door in transit design. An automatic door opener ensures that the chamber is ventilated after the process and that the water drains out of the plant house.